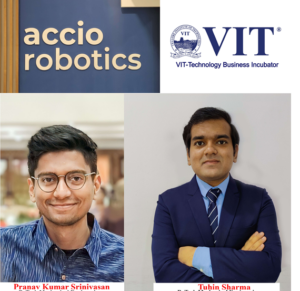

It was a chance visit to a school for the visually impaired in Chennai that set Pranav Srinivasan and Tuhin Sharma, batchmates, roommates and mechanical engineering graduates from VIT, on the path of entrepreneurship. They were both enterprising by nature and were clear that they did not want to take the conventional route that most engineering graduates take – that of joining a company. They used to discuss ideas, talk about how things get built and brainstorm about what they could do. That is when they happened to visit a school for the visually impaired. They wanted to build a product with improved technology to help the students.

Their first idea, according to Pranav, was to build a tablet equipped with a camera for the visually impaired to help scan text and the printed text converted to Braille, making it easier for the students to read. They developed a basic form of the prototype and towards the end of their engineering course, they had the prototype ready mainly to validate their idea, adds Tuhin. This is when VIT TBI (VIT Technology Business Incubator) stepped in and nurtured their dreams of becoming entrepreneurs. The prototype convinced the VIT TBI administration that the two friends were serious about what they wanted to do. Pranav and Tuhin got to know about various grants offered by different departments of the Government of India. They applied for one and were thrilled when they got a grant offered by the Department of Science and Technology. “That gave us the confidence that we have built something that people are willing to pay for and this is something that the Government sees value in,” says Tuhin.

They took a small space in VIT TBI in mid-2019, which also gave Pranav ₹5 lakhs to proceed with his product. Along with ₹10 lakhs from the NIDHI PRAYAS grant from the Department of Science and Technology, they went about putting together a small team to build the product.

Simultaneously, the two went about handling a few freelance projects of designing robots and IoT systems for others. It was early 2020 when they had a minimum viable product (MVP) to show potential customers, but the Covid pandemic struck. No one was willing to meet them and the Braille product got stuck. They were not able to proceed with it.The duo then decided to move their office to Pranav’s house in Chennai to figure out what they could do. The grant money was almost spent and they were left with a small sum that they earned through the freelance projects. “Both of us had to go back to the drawing board to figure out what direction we wanted to take because everything was in a state of limbo,” says Pranav. That is when they thought they should try their hand at robotics since they had handled a few freelance assignments and Pranav had spent a lot of time at VIT on robotics. They had a client in the US that wanted them to handle a huge project and “it was essentially money we had not seen before,” says Pranav. “It felt like a good time to double down on robotics and be able to build a product in that space –a simple mobile robot that can help us get started,” adds Pranav. They were building prototypes of a mobile robot that could move materials from one point to another. They started conceptualising this in August 2020, when they realised they would require a bigger space and some money to invest in the sensors. That is when VIT helped them out again. Also, a professor of theirs who had moved out of VIT gave them a small space in Chennai where they tried to build the first version of a robot. They also started reaching out to investors.

According to Tuhin, when they realised they needed some serious capital, they pitched to 100x.vc, an early-stage venture capital firm, which gave them a term sheet for ₹25 lakhs. They brought on board more people full-time and shifted the company Accio Robotics, which they had registered in April 2019, to Bengaluru. Accio, explains Tuhin, is Latin for summoning something. It was a phrase they got inspired from watching Harry Potter movies, he adds.

The product, according to Pranav, was a mobile autonomous robot. You take the robot around, map the area and once that is done, the robot uses its own sensors to navigate autonomously. The robot’s function was to move material autonomously from one point to another, says Tuhin. It was a generic material movement use case when they built their minimum viable product (MVP). By the third quarter of 2021, they had two customers who said they had a lot of manual movement of material in their factories, which they wanted Accio to automate. They completed five pilot projects by November for the two companies, one in the electronics component industry and the other, a textile and garment manufacturer.

These projects gave them a lot of learnings – that there was an enormous amount of customisation required for each customer and even after doing the customisation, they would be able to sell only a couple of robots. So, says Tuhin, instead of focussing on a generic use case, they decided to double down on a robot for material picking in warehouses. “We wanted to do it only for industries that have small dimension SKUs (stock keeping units) and high margin for vendors,” says Tuhin. Of all the processes in a warehouse, picking constitutes nearly 55 per cent of the total internal cost, he explains. It was a labour-intensive process and one that was a bottleneck for other processes.

Once they had decided on what they wanted to do, things started moving quickly. They raised a bridge round and came across a leading 3PL (third-party logistics player) that was willing to let them automate order picking in its warehouses. They had a fully functional MVP and they were going to bag an order from the logistics player. It was also an ideal time for them to approach investors again. Accio’s mobile autonomous robot, says Pranav and Tuhin, will be capable of automating order picking. The company is in the process of deploying six robots and is close to finalising a pre-Series A round. Pranav and Tuhin are confident that the robots developed by them will meet their customers’ expectations. They are also confident that there is a large international market to be tapped.