N. Ramakrishnan

With business running in his DNA, it was hardly surprising that Sandal Kotawala, who hails from Jaipur, Rajasthan, had the best time of his life in the four years he spent on the VIT campus in Vellore, while he was pursuing a Bachelor’s in Electrical Engineering. His parents were jewellers and he remembers travelling to different parts of the country with them when they went to supply jewellery to dealers in tourist locations. He had seen how they approached people and negotiated sales. The early lessons rubbed off on him even when he was in school. He remembers one particular occasion when he was still in primary school, when it was the practise to celebrate students’ birthdays by giving them paper cuttings. He says he bought fancy paper and sold it at nearly double the price to his classmates when they wanted to celebrate someone’s birthday in class! “There was always this business acumen,” he says and adds that, “as a person I was curious and enjoyed making things.”

His move to VIT to study engineering was the best thing that could have happened to Kotawala. He found a senior who was on the same wavelength as he was. They both hit it off. In his first year, when he says the curriculum was not heavy, he teamed up with his senior to build a machine for CMC (Christian Medical College Hospital in Vellore) to dispense paracetamol tablets. Kotawala says he shot a video of the machine and posted in on YouTube and was overwhelmed with the response. This was the beginning of many more such products he would try his hand while in college. At the end of the first year, he decided to stay back on campus instead of going home. The university canteen would work for shorter hours, which he says he was not aware and one night found himself without dinner because he went late to the canteen. “I slept hungry,” he says. That got him thinking. Could he build a machine that would dispense freshly made sandwiches. He decided to pursue that idea with a few friends. One of the professors in the mechanical engineering department helped them by taking them to a service centre where they could see how a coffee vending machine worked. Kotawala says Dr. P. Arulmozhivarman, who was then Dean of School of Electrical Engineering, encouraged him and his friends to work on the idea by giving access to various facilities such as the prototyping lab after college hours. The university too did its part by giving a grant of ₹14,000 to the bunch of students to build the sandwich dispenser. “They knew that this was not going to work as there were a lot of practical challenges. But VIT TBI (VIT Technology Business Incubator) still funded us, just to motivate us,” says Kotawala. However, this project had to be given up after Kotawala and quite a few of the others fared poorly in the semester examinations and their parents wanted them to focus on studies instead of “fooling around.”

Kotawala, however, was unfazed. He learnt how to build an app for Android. For the sandwich dispenser, they planned to have an Android app where students could place their order and also pay for the sandwich. He loved playing with microprocessors and electronics circuitry. He even built an app through which students could place orders for photocopying, pay for it and go pick up the copied material without having to wait in the long queues. He says he continued to experiment with various stuff thanks to the encouragement the university and his professors gave him. Thanks to VIT, he says, he participated in a hackathon in Bengaluru, where he teamed up with two others and won the second prize. The three of them shared the ₹75,000 prize money. This was the precursor to more such events, including in international events.

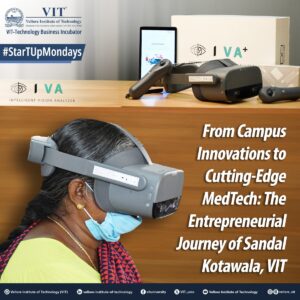

Kotawala and other students started an innovations lab at VIT and it was Dr. Arulmozhivarman who once again encouraged them by giving them space. It was thanks to the Innovations Lab, says Kotawala, that he learnt valuable lessons in recruiting and building a team. He had also got in touch with Dr. R. Venkatesh, who was then the Chief Medical Officer of Aravind Eye Hospitals in Puducherry. Kotawala developed a cost-effective camera to record eye surgeries. Dr. Venkatesh threw open the hospital’s facilities for Kotawala and the hospital became his second home. All the time, his parents continued to be worried about what Kotawala was up to! It was this association with Aravind Eye Hospitals that was to pave the way for Kotawala’s venture Alfaleus Technology Pvt. Ltd., which he incorporated in February 2018. The start-up was incubated at VIT TBI and remained there for a little over three years. The best part of being incubated at VIT TBI, says Kotawala, was that they had an office at the incubator, because of which they could recruit VIT students as interns. He also got a few grants from VIT TBI that helped his company. “The VIT TBI was a place where you need not worry about failing. You can experiment, you can get things done. We tried different models and even worked with Johns Hopkins in the US to validate the device,” says Kotawala. They had built a virtual reality (VR) headset for testing for glaucoma. The imported equipment that was being used was bulky, inconvenient for the patients and cost nearly ₹30 lakhs and the one developed by Alfaleus cost just a tenth of that. Additionally, it was a headset and there was no discomfort to the patient. Thanks to its association with Aravind Eye Hospital, they got an introduction to Johns Hopkins University, which validated the product and even published a paper in a reputed journal. Alfaleus launched the product in the early part of 2019, which is when they got an investment from a Bengalore-based company Remidio. Their first customer was an ophthalmologist in Mumbai, who wrote them a cheque within five minutes of meeting them. Alfaleus’s visual field analyser, C3 Field Analyser (C3FA), replaced an earlier product that they had. The company has numerous reputed clients. It is now working on a VR-based open low vision assist device.

According to Kotawala, Alfaleus, which is now based in Hyderabad, has raised about ₹1 crore in equity funding, including from VIT TBI Seed Fund, BIRAC JAN Care and Bangalore Bioinnovation Centre and about ₹1.5 crores in various Government of India grants and prize monies. None of this would have been possible, says Kotawala, but for the support and encouragement that he got from VIT and the professors and Aravind Eye Hospitals. (EOM).